30TPD Rice Milling Plant for Sale

Combined Rice Mill Machine | United Rice Mill

Model: 30tpd (30tons per day)

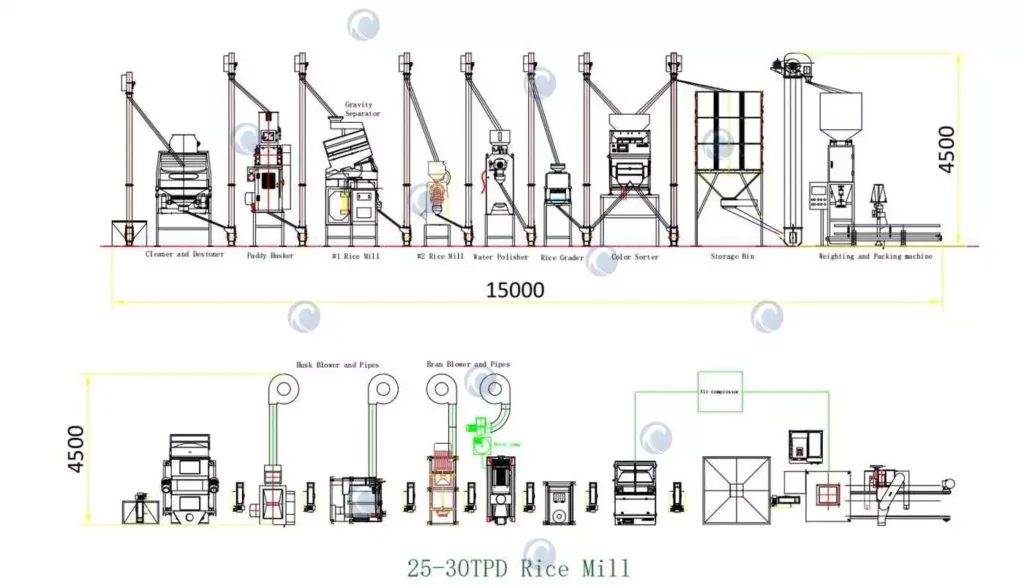

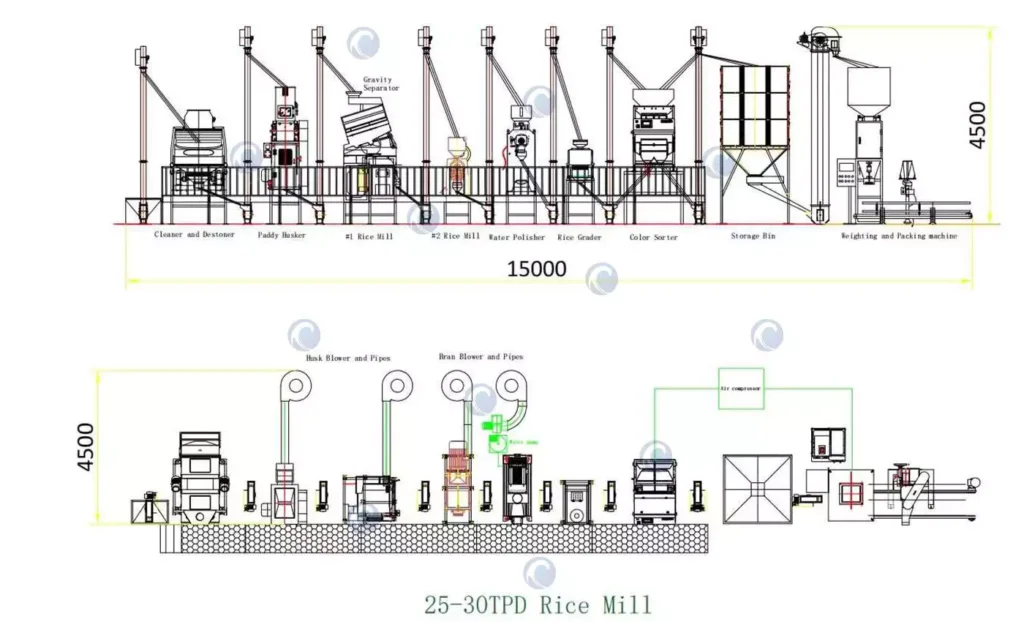

Configuration: cleaner and de-stoner, rice husker, rice miller, 2nd rice miller, polisher, rice grader, color sorter, storage bin, packing machine

Flexible collocation: steel fame

Services: customizations, after-sales service, on-site installation, online guidance, installation manual and videos, operation manual

Guarantee period: 12 months

Taizy 30TPD (30 tons per day) rice milling plant is an integrated equipment designed to meet the needs of medium and large-scale rice processing plants. This united rice mill is manufactured with advanced technology and high-quality materials, and is dedicated to realizing the entire automated operation from paddy cleaning to rice finishing.

Components of combined rice mill machine

- Cleaning section: contains vibrating screen, magnetic separator and wind separator, etc., which are used to remove impurities from raw materials.

- Hulling and separating stage: equipped with huller and grain and brown separating sieve, effectively stripping rice husk and separating pure brown rice.

- White polishing system: composed of a multi-stage rice milling machine and polishing machine to ensure the rice is white and delicate.

- Grading and screening section: using a precision grading sieve to screen the grain size of rice to ensure consistent product quality.

- Color sorting and packing: color sorter and packing machine, rejecting foreign color particles and carrying out standardized quantitative packaging.

Working principle of 30tpd rice milling plant

The 30TPD rice mill unit follows the principle of “clearing first, then milling, processing step by step”, and gradually removes the hulls, skins and polishes the rice by physical means, and improves the quality of the product with the help of modern technology, such as photoelectricity detection technology.

The whole process is scientific and reasonable, which maximizes the retention of rice nutrients and reduces energy consumption and loss.

Strengths of 30tpd complete rice milling machine

- High capacity: daily processing capacity is up to 30 tons, adapting to the demand of large-scale production.

- High efficiency: integrated design, reduce intermediate links, improve production efficiency.

- Low loss: refined process control, reduce the rate of paddy loss, improve economic efficiency.

- Environmental protection and energy saving: optimize power configuration, reduce energy consumption, in line with green production requirements.

- Excellent quality: the output of rice is of stable quality, with good color and taste, which is highly praised by the market.

Rice mill installation drawing and technical support

Taizy provides detailed installation drawings of 30TPD rice milling plant as well as professional on-site guidance services to ensure that you can quickly and accurately complete the installation and commissioning of the equipment.

Moreover, we are committed to providing you with a full range of technical advice and support, including production line layout, equipment maintenance training and so on.

Service about rice milling plant machinery for sale

As a professional united rice mill manufacturer and supplier, we not only provide perfect pre-sales consulting service, on-site installation and commissioning service, but also promise long-term after-sales support, including but not limited to spare parts supply, faulty maintenance, upgrading and replacement program.

Global cases of Taizy modern rice mill plant

Whether in emerging markets or traditional agricultural regions, our 30TPD rice milling plant has won wide acclaim for its high efficiency, high quality and full range of services, and has helped many rice processors to upgrade their business. Below are a few typical cases

- A large-scale rice processing plant in Southeast Asia: After the introduction of our 30TPD rice milling machine, the plant not only greatly increased the daily processing capacity to meet the local and export market demand, but also significantly improved the quality of rice through advanced color sorting and polishing technology.

- A family-run rice enterprise in South Asia: Before using our rice milling plant, the enterprise faced capacity and technical problems. After installing and putting into use the 30TPD unit, its productivity has been significantly improved, and operating costs have been reduced at the same time.

- A government-funded grain processing project in Africa: Taizy’s 30TPD rice milling unit was adopted as the core production equipment for this project, effectively promoting the development of the local rice industry. The united rice mill‘s high efficiency and energy saving features and stable output quality were well received by the local government and farmers, helping to realize the goal of food self-sufficiency.

- A cooperative association in Latin America: Several small cooperatives jointly purchased our 30TPD combined rice mill machines to build a modern rice processing line. Thanks to the outstanding performance of the unit and customized service support, members of the cooperatives have been able to share resources, reduce costs, improve product competitiveness and broaden sales channels.

Contact us for more rice milling plant details!

For more information about our 30TPD automatic rice mill machine, please contact us directly, our professional team will provide customized solutions and competitive price according to your specific needs(such white rice production capacity, configuration, etc).

We look forward to working with you to create a bright future for the rice processing industry!