15TPD small scale rice milling machine plant

Industrial Rice Milling Machine | Mini Rice Mill

Model: 15TPD rice mill plant

Capacity: 15t per day(700-800kg/h)

Configuration: ①standard rice mill with polisher & rice grader; ②standard rice milling with color sorter & packaging machine; ③standard rice miller with 2 rice millers(totally) & polisher

Features: Flexible collocation, multiple configurations, customization

Services: After-sales service, on-site installation guidance, etc

Brand: Taizy

This complete rice mill plant can process 15 tonnes of paddy per 24 hours. This kind of equipment is usually used for small and medium-sized rice mills or farmers to process paddy, which can be transformed into white rice for our daily consumption.

Our small scale rice mill has different configurations to meet your demands, so it’s popular among worldwide.

Three types of 15TPD complete rice mill plant for sale

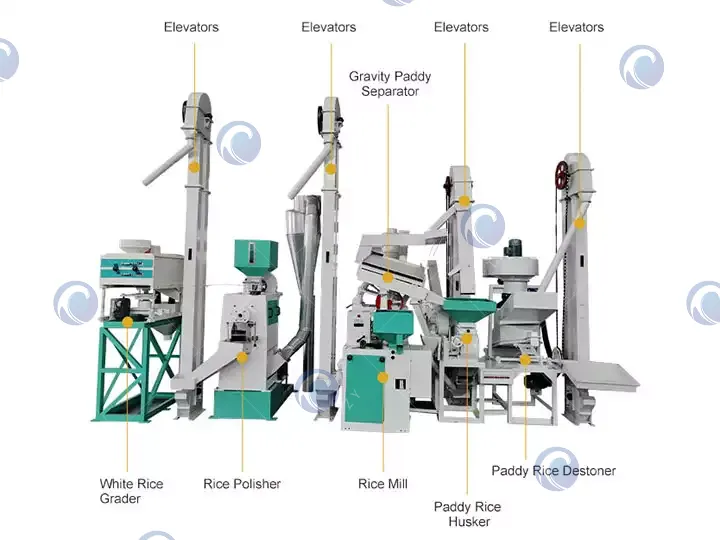

Type 1: 15TPD industrial rice milling machine (with polisher and rice grader)

This configuration adds a polishing machine and rice grading machine to the standard rice milling machinery configuration. The polishing machine is used to polish the surface of the rice to make it smoother and brighter, while the grading sieve screens the rice according to the size of the grains to ensure consistent product quality.

Structure of mini rice mill

Advantages of machine for rice mill

- The polishing machine can further improve the appearance and quality of rice, increasing market competitiveness.

- Rice grader machine can accurately classify the rice to meet the needs of different consumers.

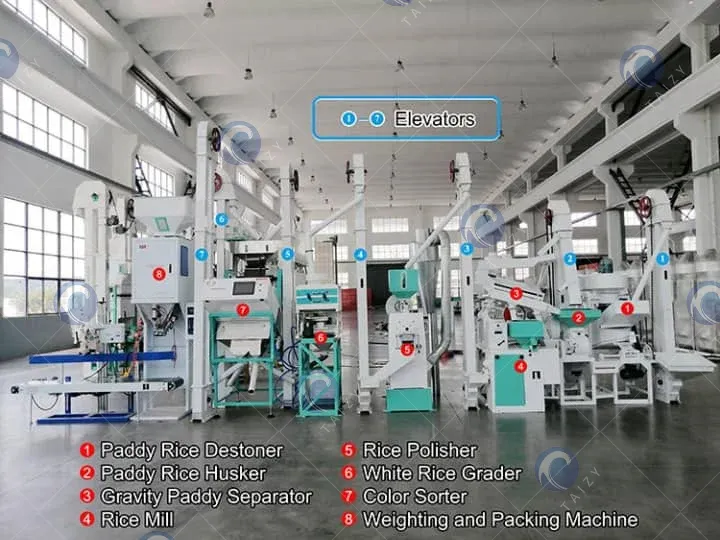

Type 2: 15TPD automatic small rice milling machine (with color sorter and packing machine)

Based on standard configuration, this collocation adds the color sorter and packaging machine.

- The color sorter identifies the different colored grains in the rice through photoelectric sensors and rejects them to ensure the purity of the product;

- The packaging equipment can automatically complete the rice metering, filling, sealing and other operations according to the customer’s needs.

Components of combined rice mill machine

Strengths of complete rice mill plant for sale

- The color sorter improves the purity and quality of the product and enhances the brand image.

- Automated packaging equipment greatly improves production efficiency and reduces labour costs.

- Packed rice can be sold directly, convenient for transport and storage.

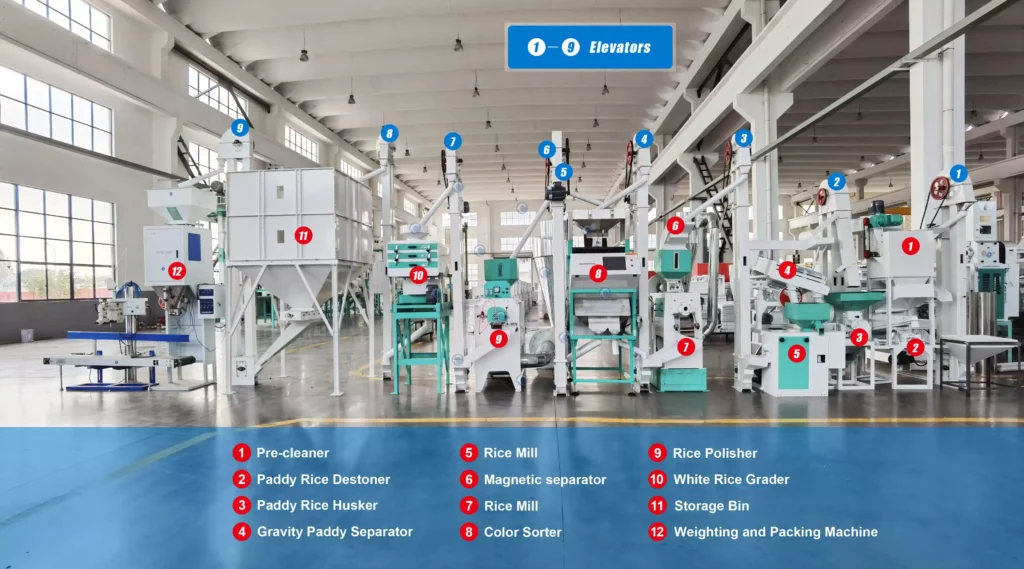

Type 3: High standard 15TPD mini rice mill unit (2 rice millers and polisher)

The main feature of this configuration of rice milling unit is that it adopts double-channel rice milling and water mist polishing technology. The double-channel rice milling can more fully remove the bran from the outer layer of brown rice, making the rice whiter; while the water mist polishing can improve the lustre and taste of the rice

list of machines used in rice mill

Highlights of rice milling machine for sale

- The use of two-channel milling can effectively improve hulling efficiency and rice utilization.

- Water mist polishing can increase the smoothness and brightness of rice and improve the product quality.

Workflow of complete rice milling plant machinery

For the complete rice mill plant, a rice processing line usually consists of the following steps: cleaning, hulling, grain and brown separation, milling, polishing, grading and packaging.

For the complete rice mill plant, a rice processing line usually consists of the following steps: cleaning, hulling, grain and brown separation, milling, polishing, grading, color sorting and packaging.

Destoning

This step is to remove impurities from paddy rice, like straws, small stones, etc., for preparation for the nest rice processing.

Hulling

When the paddy rice comes to this step, the rice husks should be removed. Then, the brown rice comes for the next rice milling.

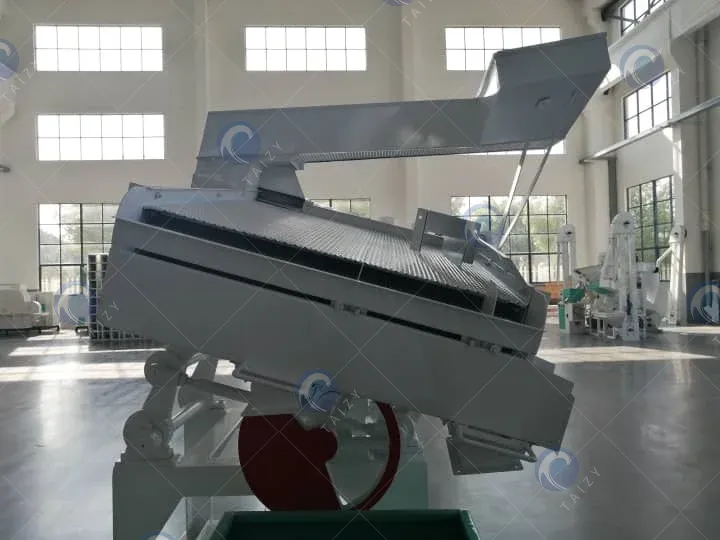

Paddy rice and brown rice separation

Because paddy rice and brown rice mix together, and the best raw materials for rice milling machine are brown rice, the gravity separator is set up here to separate the two.

Rice milling

The brown rice comes into this rice miller for getting edible white rice. Sometimes more stages of rice milling machines are also placed to get whiter rice, which mainly depends on your needs.

Polishing

When milling rice, to make the final product look whiter and more beautiful, we also equip the rice milling machine with water mist polishing.

Rice grading

Because of the inconsistent size of the white rice particles produced, the use of white rice grader is the rice particles are collected together consistently, so that it is convenient to classify the rice for sale.

Color sorting

After grading the rice, sometimes the color of the rice is not the same, so a color sorter is used to pick out the rice of different colors. This step and rice grading can be exchanged.

Packaging

After grading and colour sorting, the rice looks beautiful and is ready for final packaging and sale.

How about the fully automatic rice mill plant cost?

The cost of complete rice mill plant depends on a variety of factors, such as equipment model, configuration, brand, place of purchase and so on.

Different configurations of the same model have different prices. To get accurate information about the price of the machine, you can contact the manufacturer directly.

Taizy Machinery: world-famous rice mill machine manufacturer

Taizy Machinery is a globally renowned manufacturer of rice processing machines, offering all types of rice processing equipment, ranging from small and medium-sized home-based rice milling machines to large-scale fully automated production lines. Our complete rice mill plant is recognized by customers worldwide for its high quality, high efficiency and excellent after-sales service.

How do you start rice mill business with 15TPD mini rice mill?

To start a rice processing business with Taizy 15TPD complete rice mill plant, you can follow the steps below:

- Market research: Understand the demand and competition in the local rice market and assess whether there is enough room for your product to be sold. At the same time, make sure there is enough supply of raw materials (i.e. paddy) to meet the production demand.

- Equipment purchase: Contact Taizy Machinery to purchase a suitable 15TPD mini rice processing machine. Choose different configuration options according to your needs.

- Factory site selection and construction: Choose a suitable location to establish a rice processing plant, considering factors such as convenient traffic and sufficient water supply. Reserve enough space for equipment installation and ensure stable power supply.

- Equipment installation and commissioning: We have professional technicians to install the equipment in place and carry out the necessary commissioning work to ensure that the machine can operate normally.

- Service support: Taizy provides customers with quality service and support, including after-sales maintenance and technical support, to enhance customer satisfaction and loyalty.

To set up a complete rice mill plant, the above is for your reference. You can contact us for more machine details. And our staff is professional, and he can provide the best solution and quote to strat your rice business!