40TPD Automatic Rice Mill Plant

Brand: Taizy

Model: 40TPD

Capacity: 40 tons per day

Flexible configuration: 2 or 3 rice millers

Advantages: Fully automatic, high efficiency, flexible configuration, good quality, long service life.

Service: After-sales service, on-site installation guidance, video manual, etc.

Warranty period: 12 months

This 40tpd automatic rice mill plant is to process grain raw materials such as paddy rice into high-quality edible white rice with a capacity of 40 tons per day. This kind of rice milling plant features high efficiency, energy saving and automation.

Our modern rice mill plant has different configurations, such as 2 rice millers or 3 rice mills, depending on your demands. If interested, welcome to contact me for more machine details!

Multiple configurations of 40tpd automatic rice mill plants

Configuration 1: Rice mill machine with 3 rice millers & rice grader or color sorter

This collocation consists of cleaner, de-stoner, rice huller, gravity paddy separator, 3 rice milling machines, and rice grader or color sorter. This makes rice milling more automatic and conveneient.

Configuration 2: Rice mill processing plant with 3 rice mills & rice grader & polisher & color sorter

More functions are added based on configuration 1. Rice grader, polisher and color sorter work together for better and white edible rice production.

Configuration 3: Rice mill line with 3 rice mills & rice grader & storage bin & polisher & color sorter

Based on configuration 2, this one adds the storage bin in the rice processing, which is more effective during rice milling.

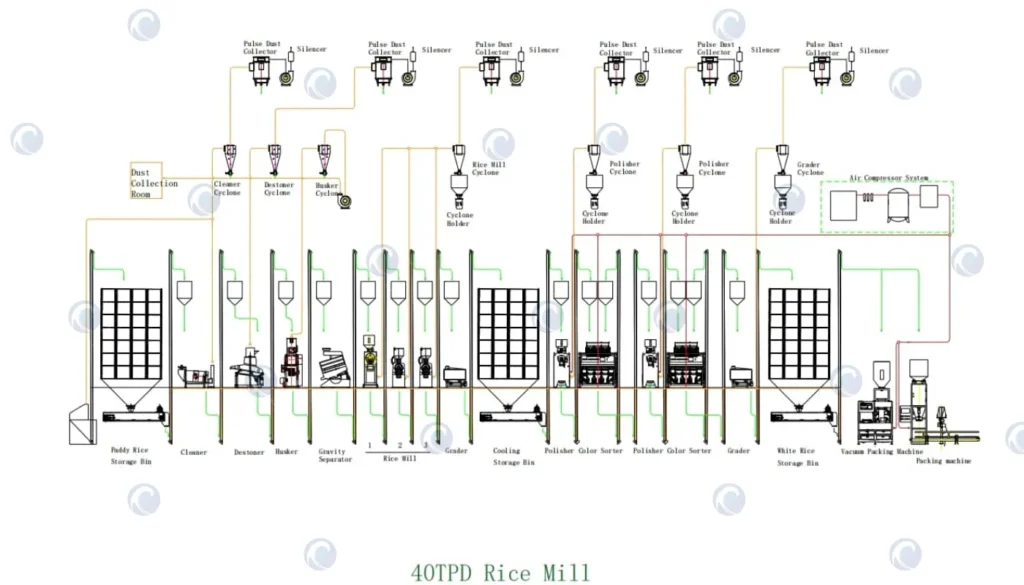

Workflow of automatic rice mill plant

The workflow of the 40tpd rice mill processing plant usually includes de-stoning, rice hulling, rice milling (2 or 3 mills), grading and color sorting.

- Firstly, the raw materials are de-stoned to remove impurities;

- This is followed by husking, where the grain is cleaned;

- It then enters the rice milling process, which may include 2 or 3 milling processes to ensure that the grain is fully milled;

- This is followed by grading, where the milled rice is graded to distinguish between different qualities of rice;

- Finally, color sorting, using color sorting machines to check the rice grains, remove stray colors and inferior products, and finally obtain high-quality finished rice.

The whole workflow is highly automated, which can improve production efficiency and product quality.

Plant layout of rice mill

A proper plant layout can maximize the use of space and improve productivity. A typical layout of a rice processing plant usually includes a raw material storage area, cleaning area, milling area, packaging area, and so on.

- Raw material storage area: Usually located on one side of the plant to facilitate the storage and transportation of raw materials.

- Cleaning area: Used to clean raw materials such as paddy to remove impurities and undesirable particles.

- Milling area: The core area of rice processing, including the milling unit and related equipment, which is used to process the paddy into rice.

- Packaging area: Used to package and encapsulate the processed rice for transportation and sale.

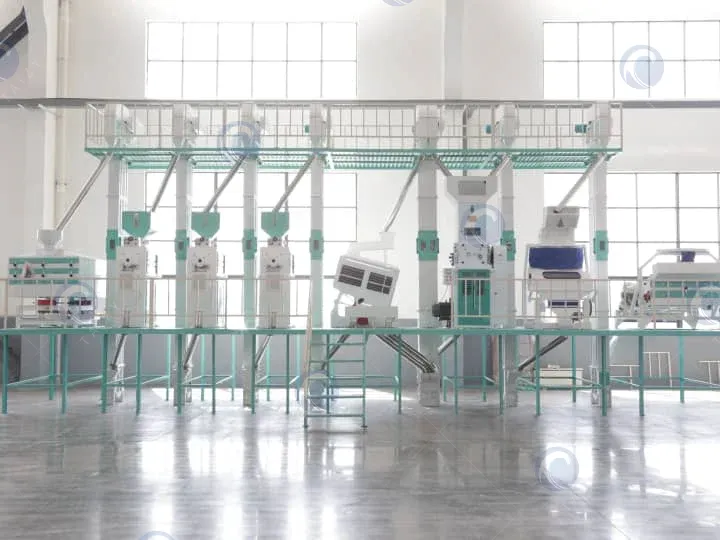

Installation drawings of complete rice milling plant machinery

After purchasing our machines, we will provide installation plans and drawings for your reference, and if necessary, we will send engineers to the site to help you.

Strengths of commercial rice milling plant machine

- High efficiency: the machine is able to process large quantities of rice quickly, increasing productivity;

- Energy efficiency: by the use of advanced energy-saving technologies in the design of the machine, reducing energy consumption;

- Ease of operation and maintenance: makes it easy for operators to operate and maintain the machine, reducing labor costs;

- Strong adaptability: the machine can adapt to different types and qualities of rice to ensure that the quality of the products processed is consistent.

How much does the fully automatic rice mill plant cost?

The cost of a fully automated rice processing plant varies depending on a variety of factors, including production scale, equipment configuration, and technology level.

Generally speaking, a fully automated rice processing plant costs more, but has higher long-term benefits and productivity compared to a manually operated plant.

The cost of a fully automatic rice mill plant usually includes equipment purchase cost, installation and commissioning cost, and plant construction cost. Depending on different needs and budgets, the cost of a fully automated rice processing plant may vary and needs to be assessed and calculated on a case-by-case basis.

If you want more details, please contact us now for more machine details and prices!

Inquiry now for rice milling plant machine price!

Request a quote now to get rice processing plant machine price! We offer high-quality and efficient equipment (15tpd mini rice mill plant, 25tpd rice milling plant, 60tpd rice mill, etc)for your rice milling needs. Contact our customer service team for more information!